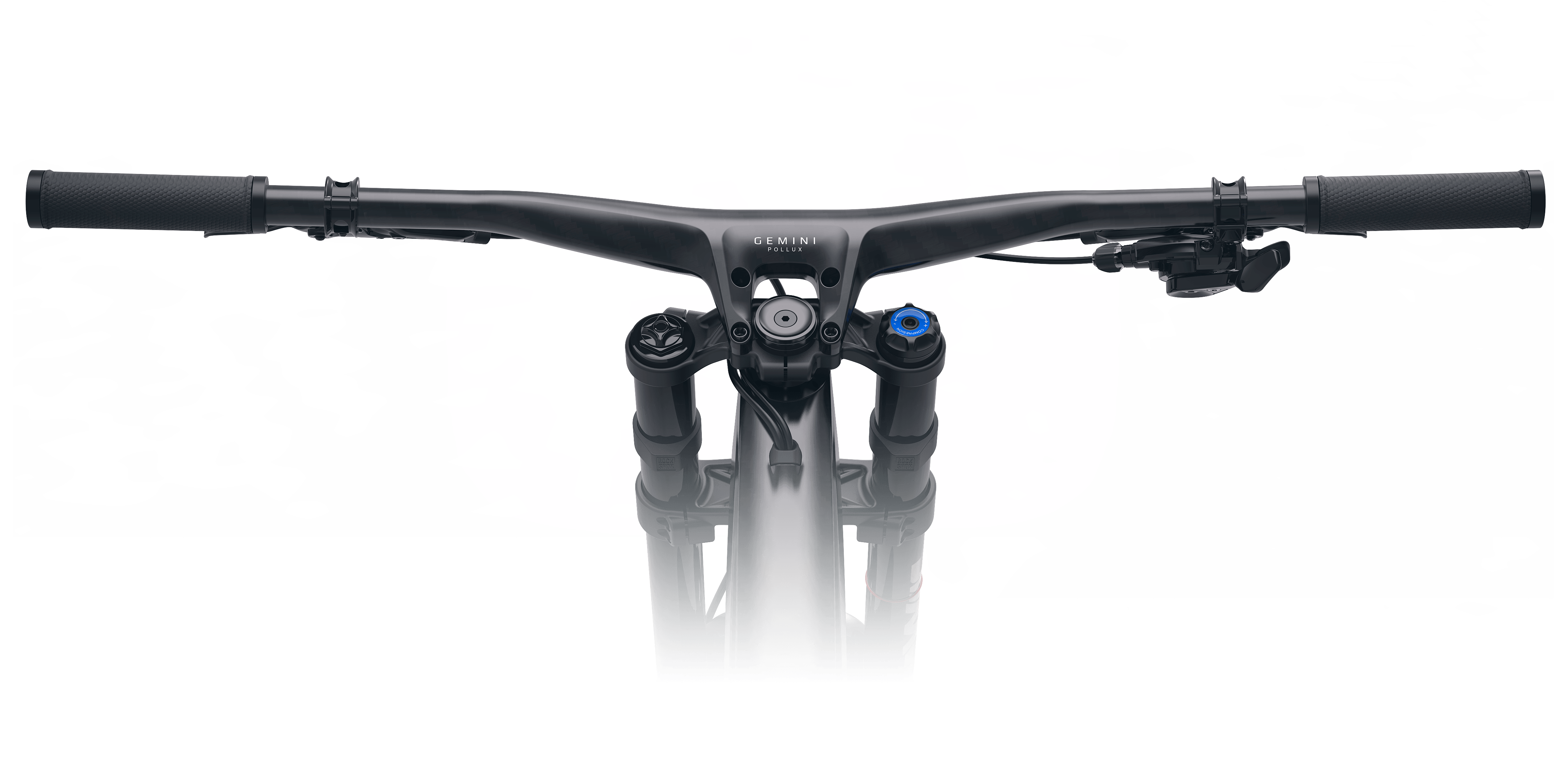

POLLUX

The first DH integratedhandlebar

▼

DESIGNED, DEVELOPED AND MANUFACTURED IN BARCELONA, THE FIRST DOWNHILL INTEGRATED HANDLEBAR

Intended for taking the control of your downhill bike to the next level, Pollux is the result of many hours of design and engineering in order to create a piece of maximum resistance and minimum weight, which has been specifically made for downhill.

Testing in Whistler – 2017

Boris Beyer

A COCKTAIL OF DESIGN, ENGINEERING AND THE BEST MATERIALS

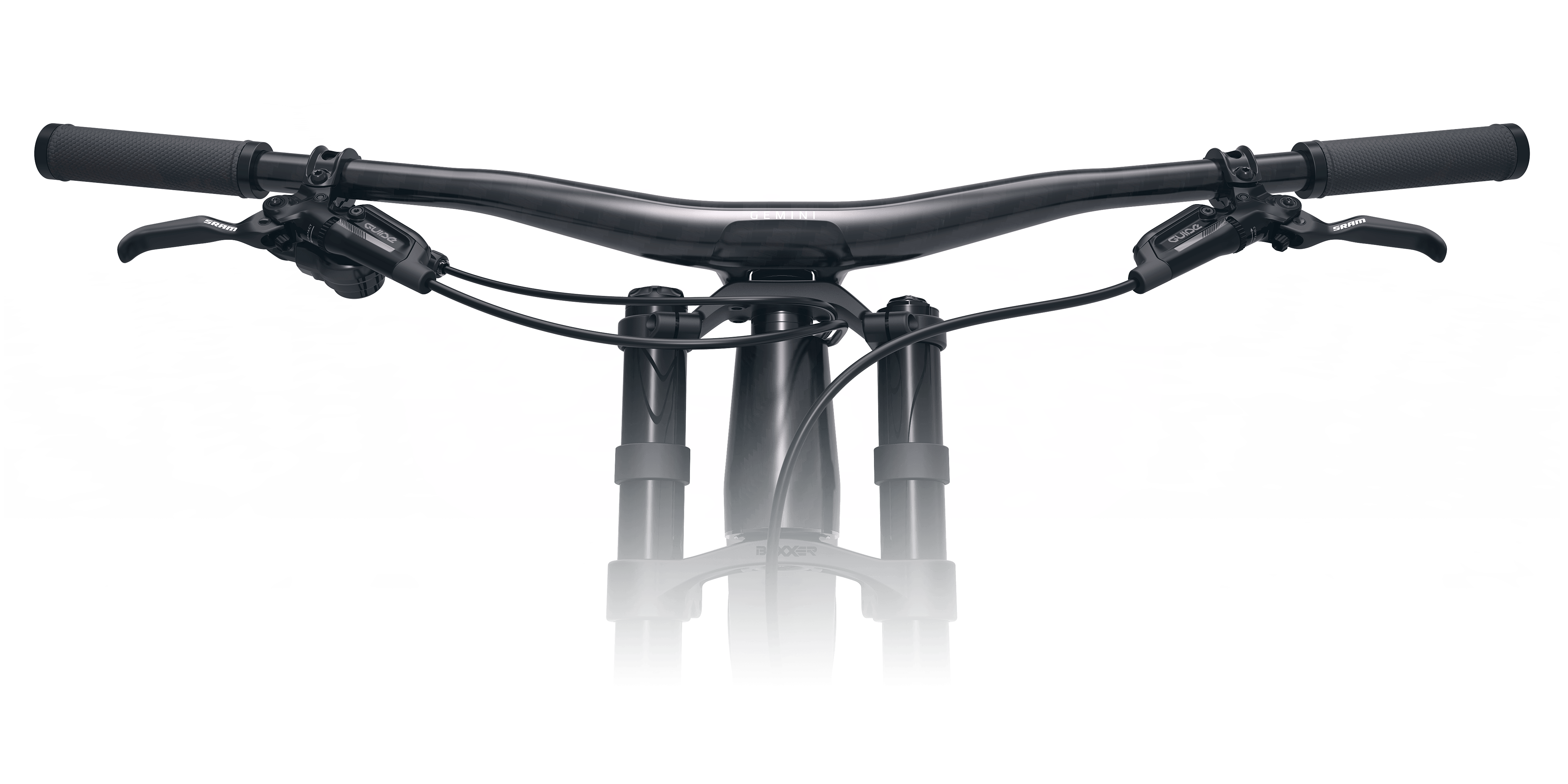

Pollux has been designed from the ground up and made from carbon to take the maximum advantage of this material, helped by the most advanced calculation software and implementing a simple and functional design—this is why it is unlike anything you have seen before.

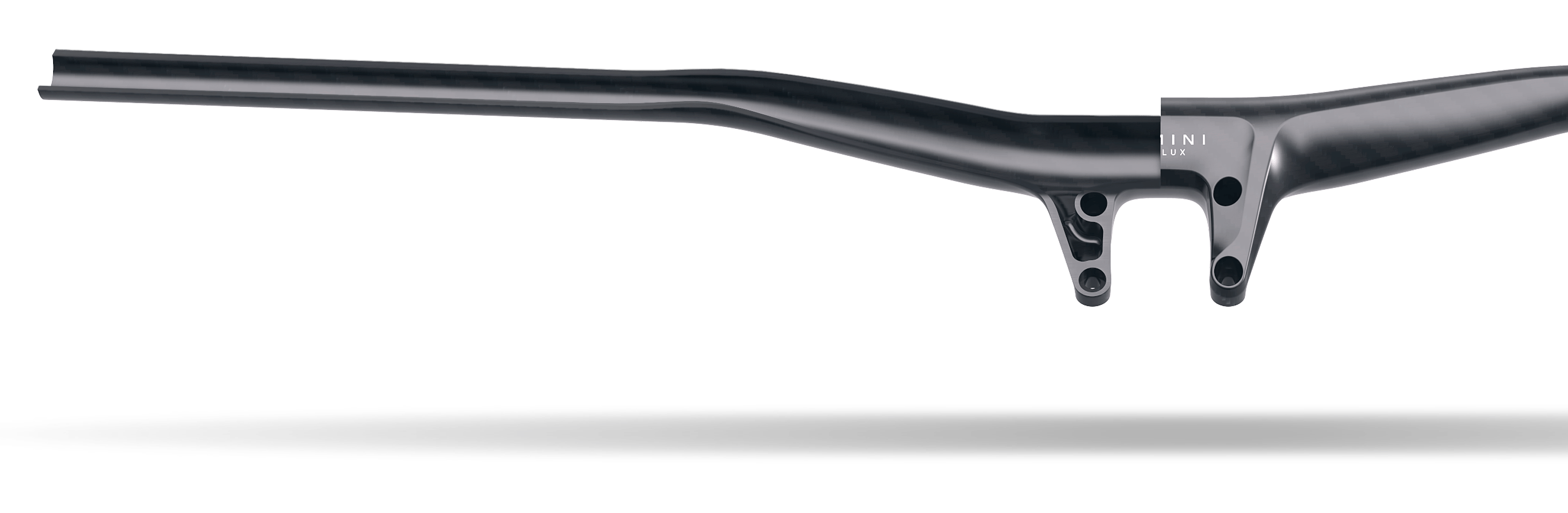

FROM ONLY 255 g. THANKS TO THE UNIBODY DESIGN, MORE RESISTANCE WITH LESS MATERIAL

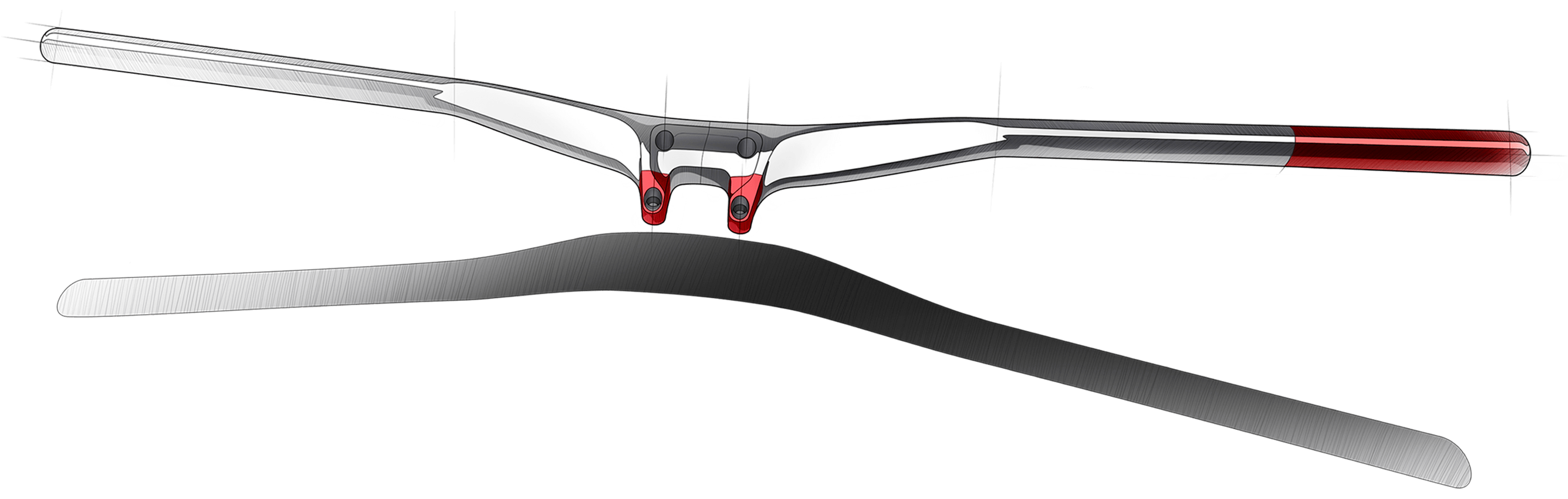

The engineering work has endeavored to simplify and improve the stress distribution, reducing the areas where stress peaks accumulate and making it possible to increase resistance with less material.

NO ASSEMBLY STRESSES

By eliminating the joint between the stem and the handlebar, stresses caused by assembly preloads are taken away, as well as the areas subject to compressions that warp the handlebar and are conductive to the delamination of the fiber layers, decreasing resistance.

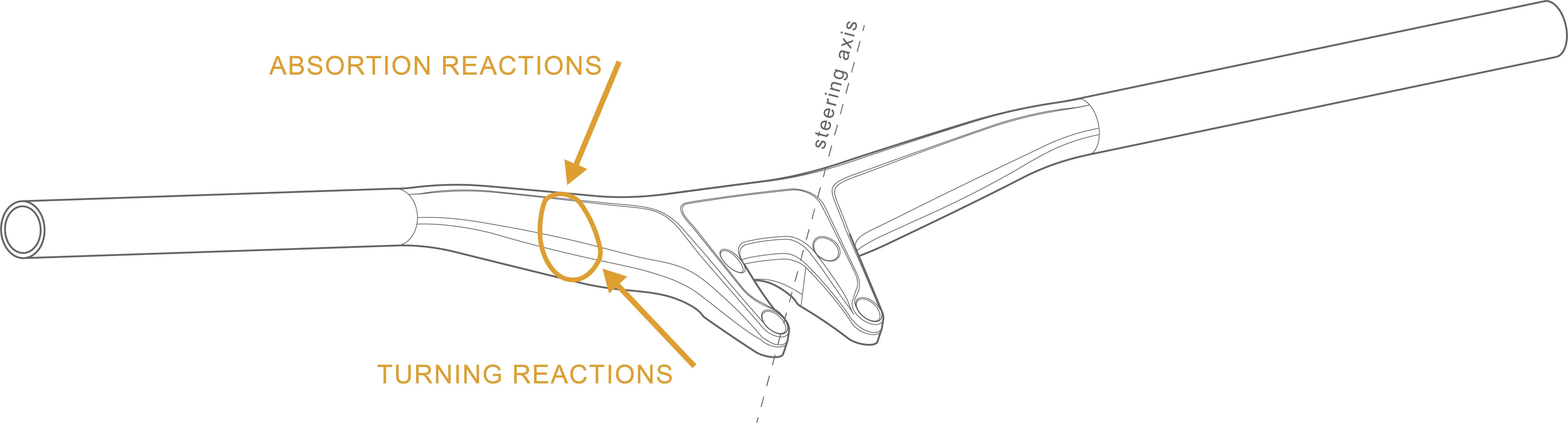

STRESS DISTRIBUTION

The continuity of the material between the stem and the handlebar eases stress distribution over a larger area, so that the stresses flow along the handlebar, eliminating high-stress areas and, thus, increasing its final resistance.

GMN SECTION

The circular cross sections perform equally in all directions, this is why we have developed the GMN section with two basic purposes: decreasing hand fatigue arising from vibrations and forces, and increasing reactivity and control when turning.

VERTICAL ABSORPTION

By reducing the vertical section we have achieved an increased absorption of vertical impacts and vibrations, this translates into less hand and arm fatigue, since the handlebar absorbs them, allowing you to keep a high downhill pace for a longer period of time.

TURNING REACTIONS

By enlarging the horizontal section, we have managed to increase inertia, increasing the rigidity of the handlebar against any force exerted by the pilot when turning on the terrain. This translates into a more direct and reactive control, providing a greater steering precision.

Testing in Whistler – 2017

Boris Beyer

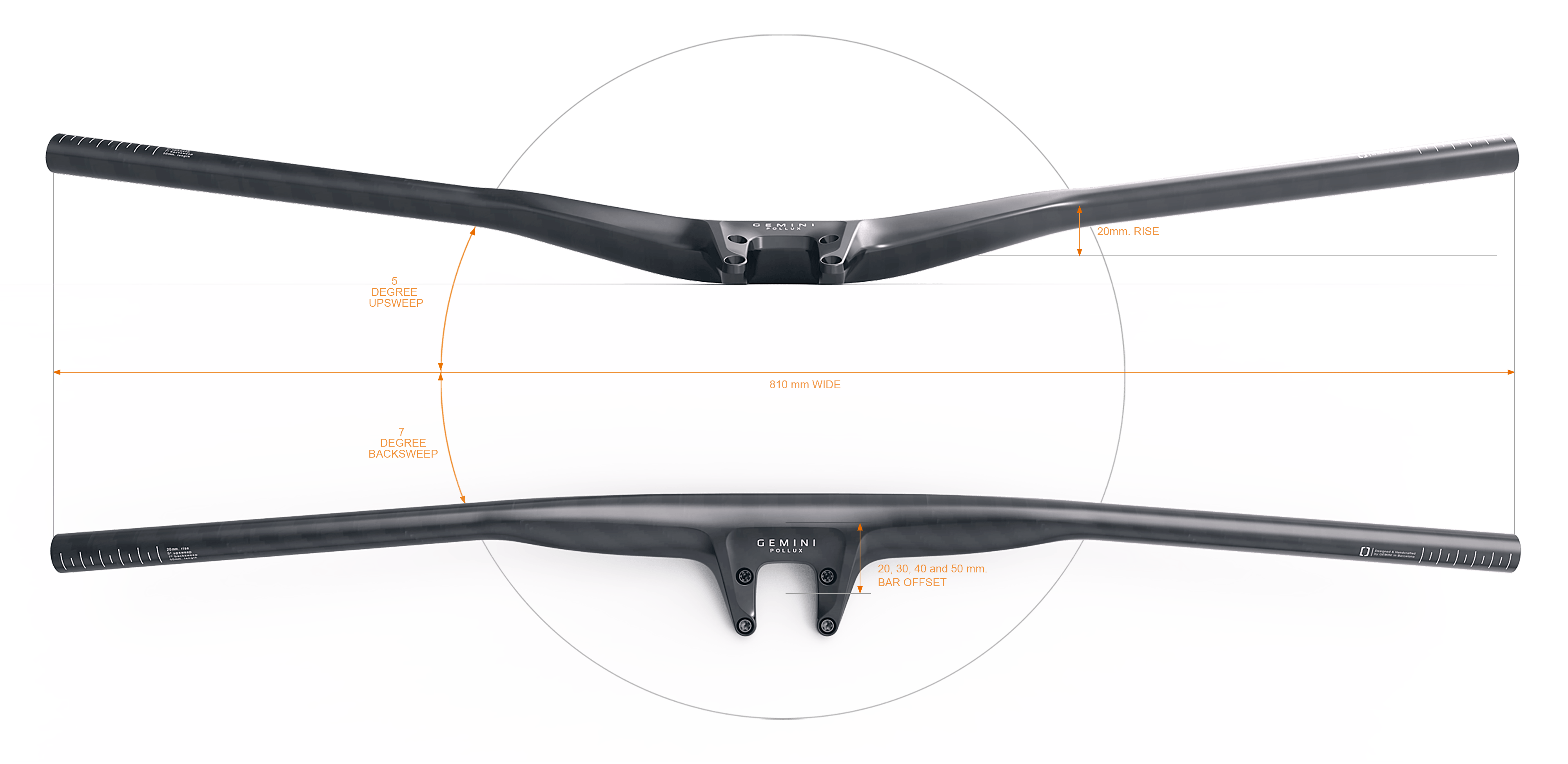

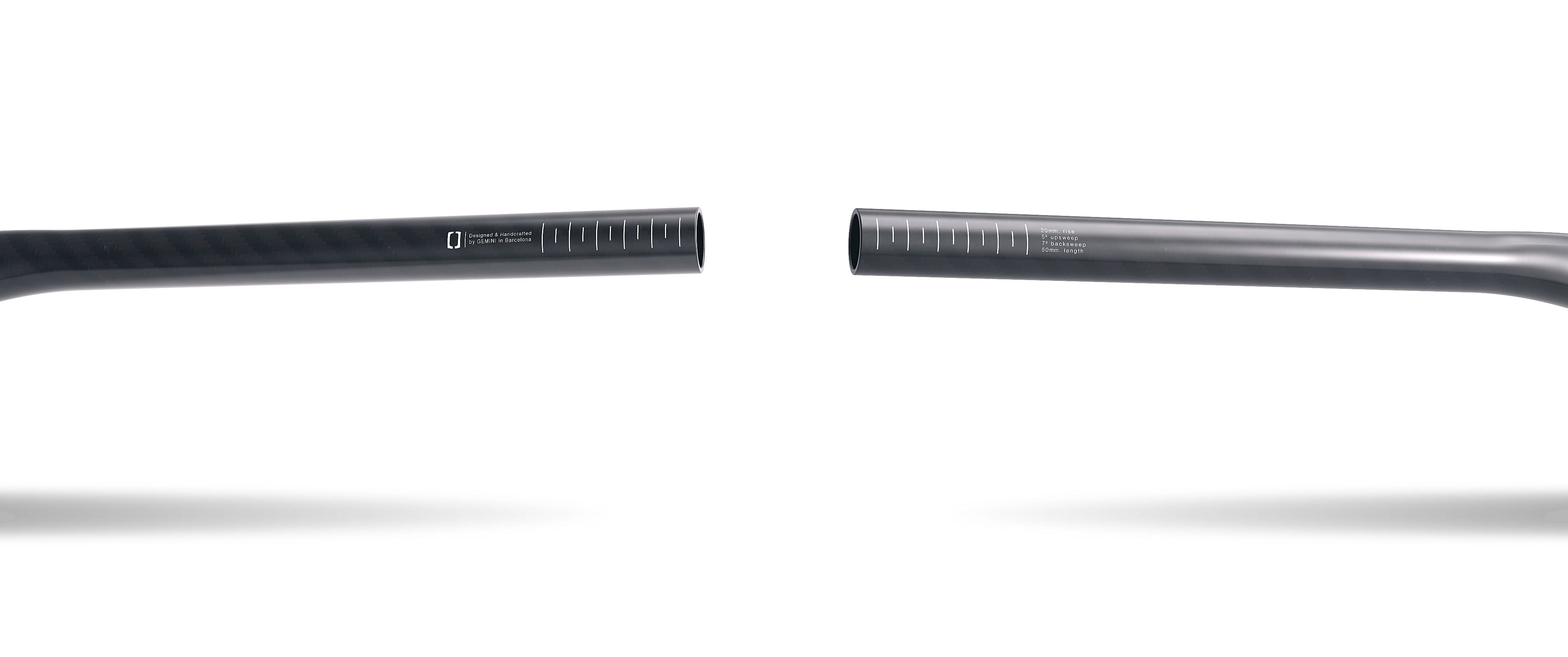

OPTIMIZED GEOMETRY FOR DOWNHILL IN 20, 30, 40 AND 50 mm OF LENGTH

POLLUX geometry is designed for you to have the greatest control and maximum comfort, to be adapted to your body with a perfect natural position and decrease fatigue in the longest and toughest downhills.

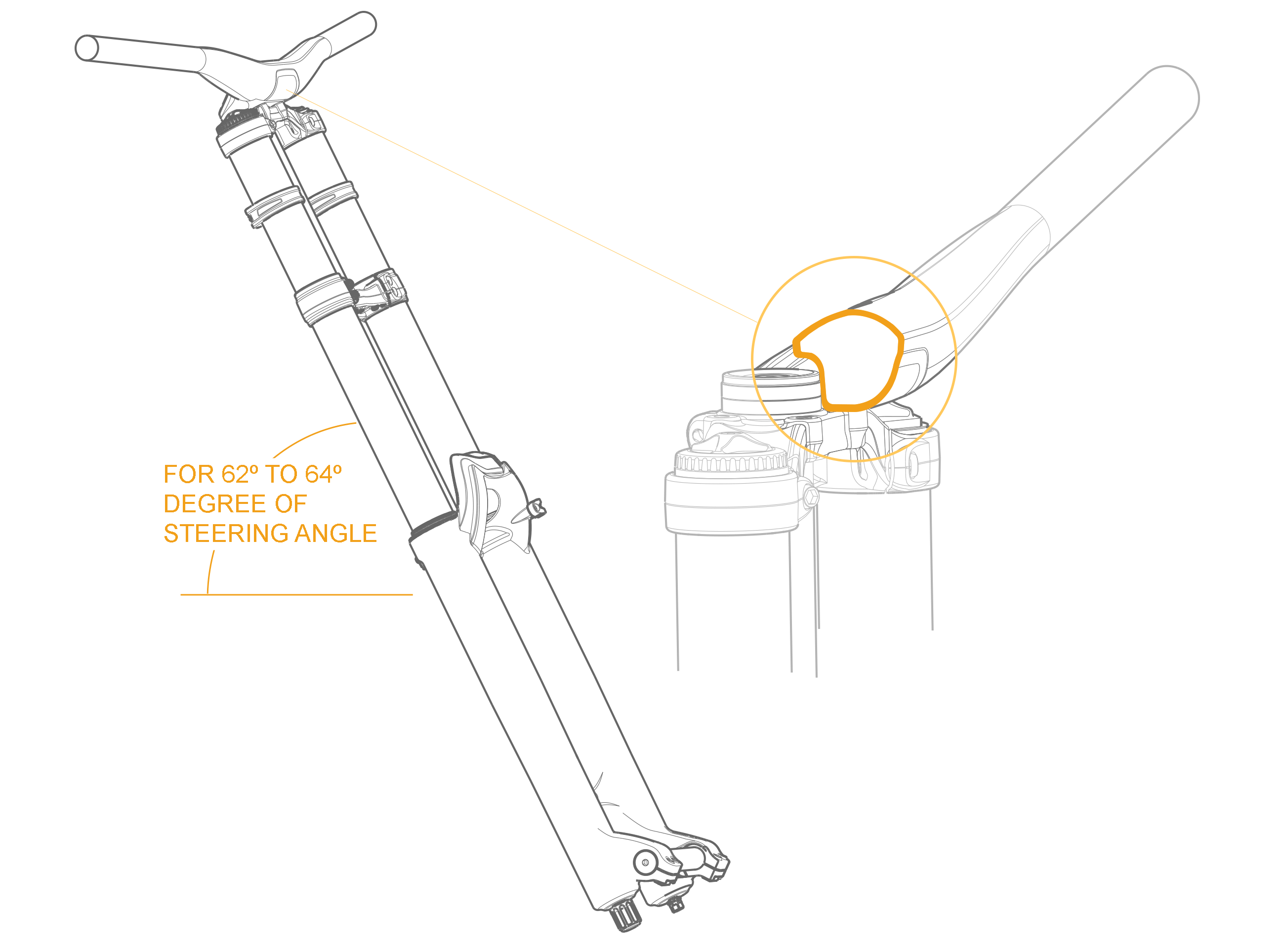

DOWNHILL GEOMETRY

Pollux is especially designed to be implemented in bicycles with steering angles between 62 and 64 degrees—its entire geometry is indented to work in that position and give you increased control and absorption.

LOWERED POSITION

The unibody design allows us to assemble the cockpit directly over the upper crown, thereby achieving a really low position. In order to achieve this, we have equipped it with a compartment for the headset cap, so you can adjust the geometry of your bicycle by sliding the crown up or down without having to cut the head tube, as you would have to do with a traditional handlebar.

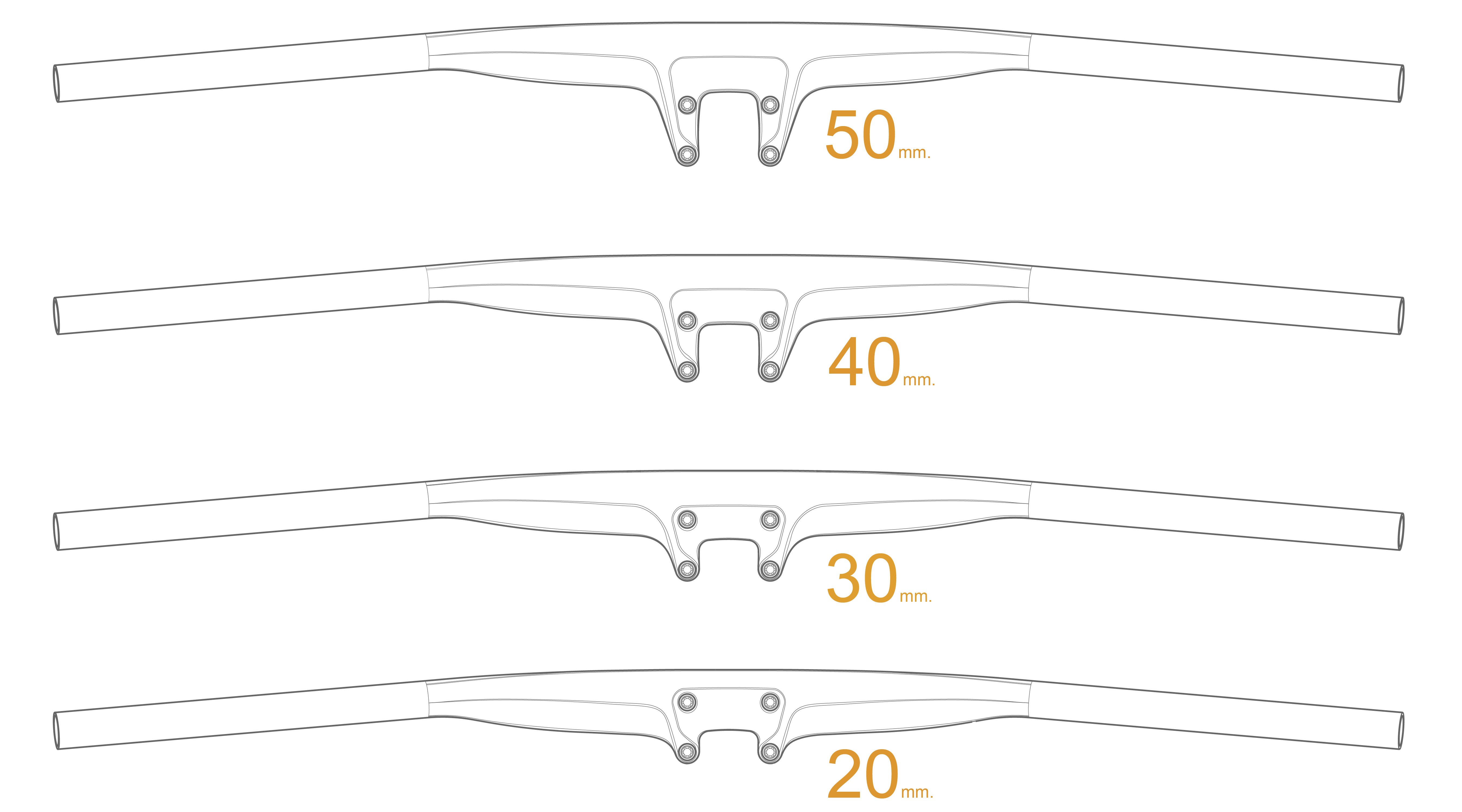

CHOOSE THE PERFECT LENGTH FOR YOU

POLLUX is available in different lengths of stem, so that you can choose the most suitable position for your style and the geometry of your bike, with lengths of 20, 30, 40 and 50 mm.

Testing in Whistler – 2017

Boris Beyer

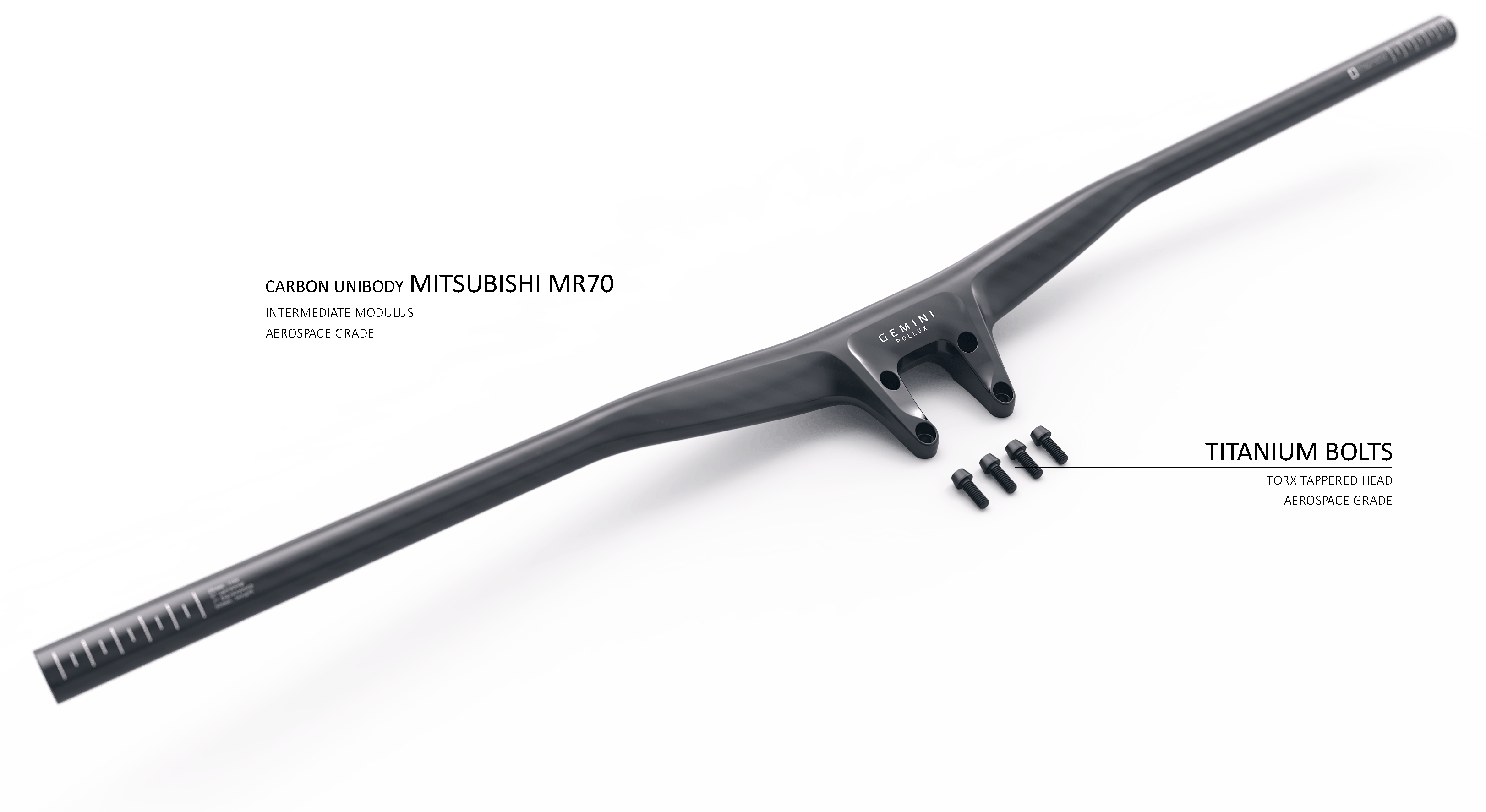

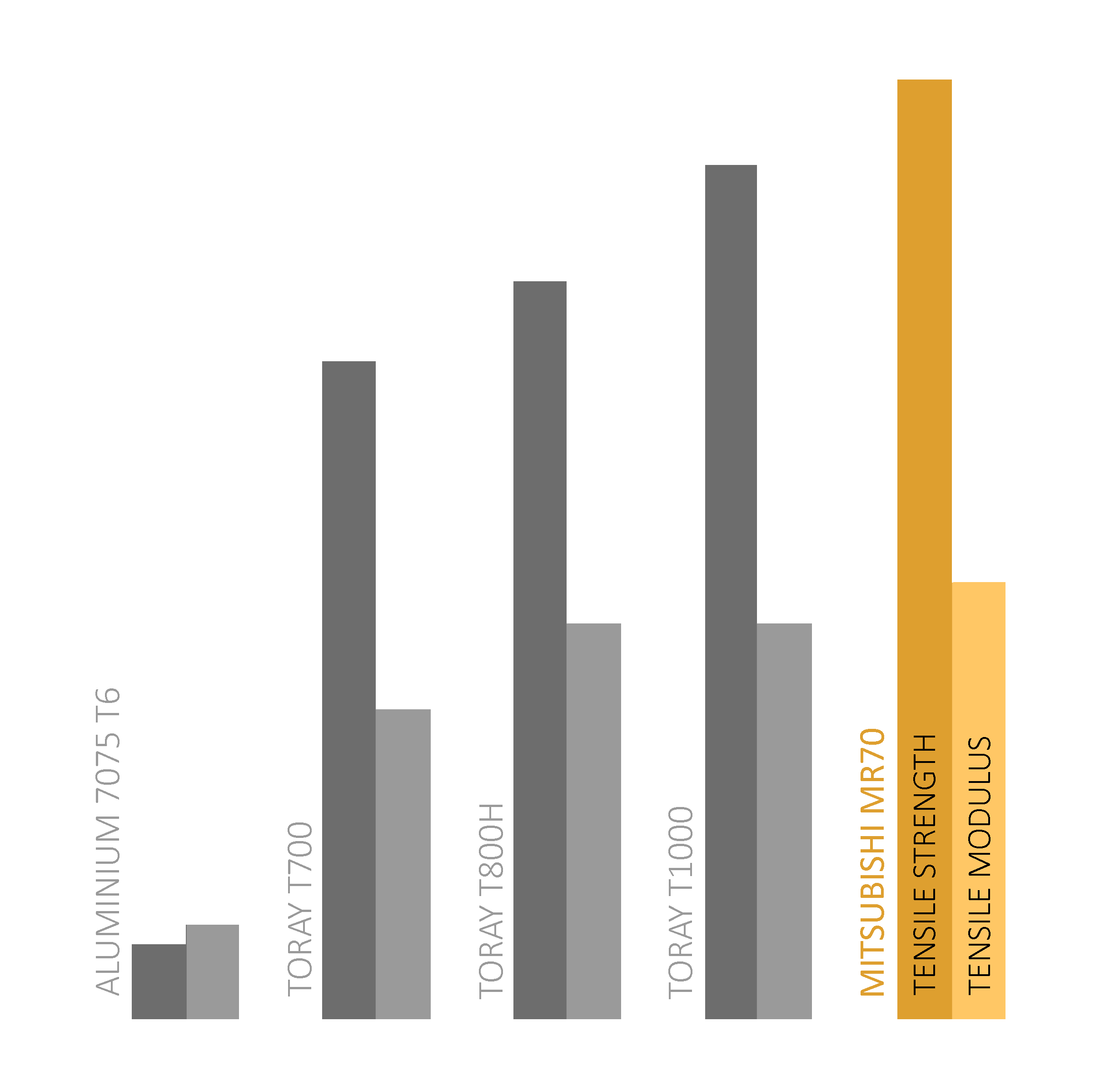

POLLUX IS MADE FROM THE BEST CARBON FIBER

It could only be made from the best carbon fiber of intermediate modulus currently available on the market, MITSUBISHI MR70, plus an optimized lay-up to be more resistant to impacts and a manufacturing process developed specifically to make top-quality components.

CARBON FIBER

Carbon fiber is not the same everywhere; for Pollux, we have chosen the most resistant carbon fiber, with an intermediate modulus. Mitsubishi MR70 is a latest generation, high-end carbon fiber, developed for the most discerning clientele in the aerospace industry and it is of European production. This is the best way to be able to ensure optimum performance of the handlebar and to increase resistance by lowering weight.

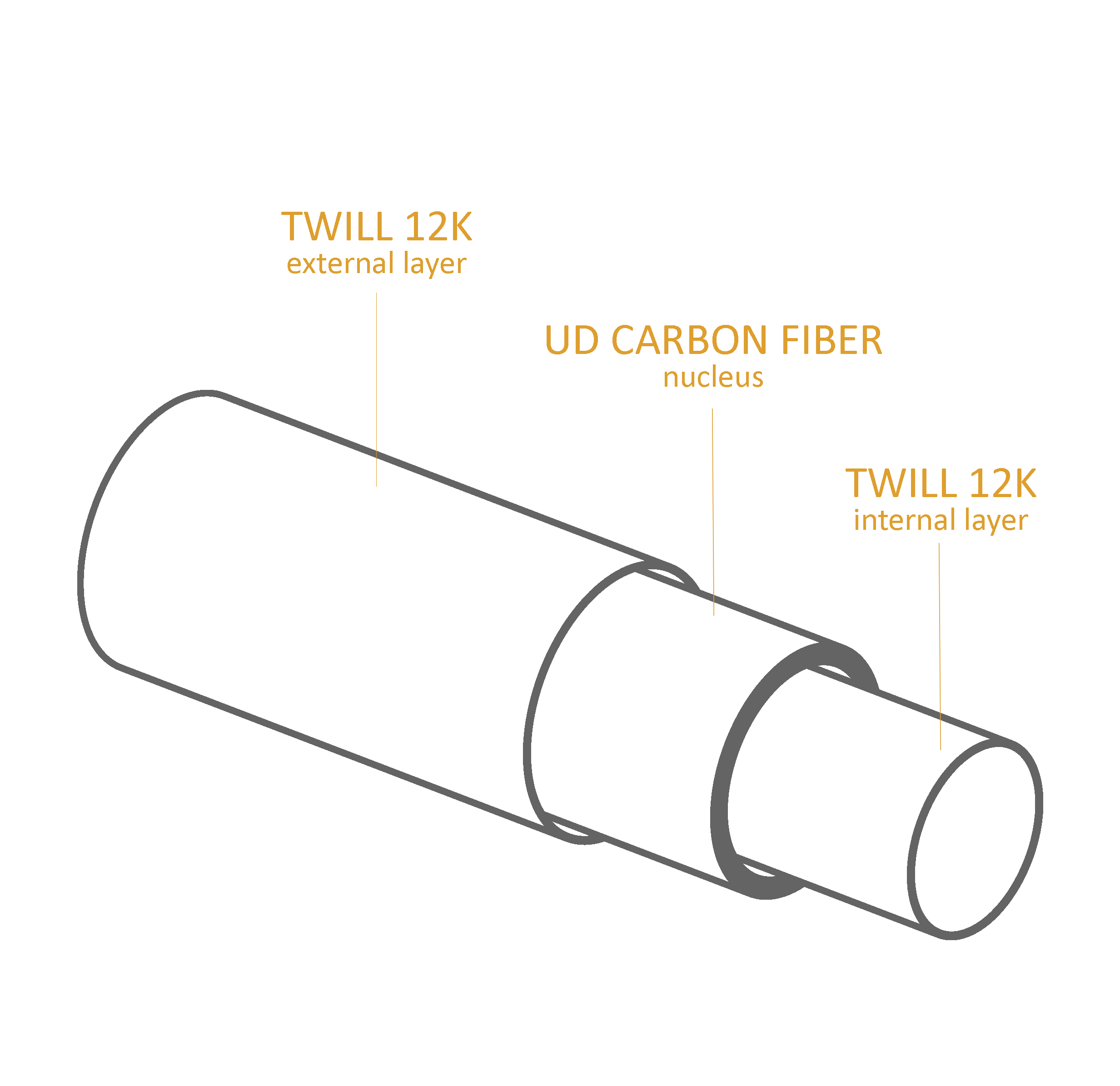

CONSTRUCTION

The material properties are really important, but so is the building structure of the parts, this is why we use a “sandwich” structure, using twill carbon fiber to increase its resistance to delamination due to impacts, and a core UD carbon fiber that ensures getting the best mechanical and structural properties of the fiber.

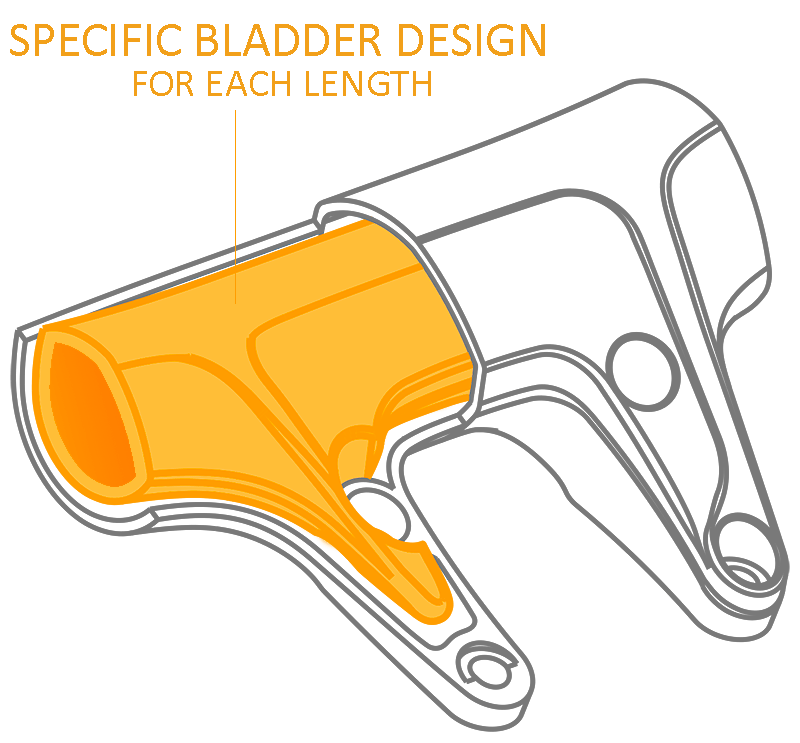

SPECIFIC BLADDER DESIGN

What cannot be seen is as important as what can be seen, this is why we have created a specific bladder for every handlebar size, which allows us to adapt it perfectly to the handlebar shape and obtain a perfect fiber compaction, avoiding the formation of wrinkles and resin pools.

TITANIO

The best material to be in contact with carbon fiber is titanium. Thanks to its chemical properties, it acts as a noble material, avoiding any kind of galvanic corrosion—this is why we have chosen it for the screws, as well as because of its balance of mechanical properties and weight.

TESTED THROUGH THE MOST DEMANDING TESTS IN THE LABORATORY AND IN THE WHISTLER DESCENTS

Pollux is a top-quality, maximum resistance piece of engineering. It has been tested in the laboratory and has overcome the most abusive loads that the industry puts on a downhill handlebar, with stresses well above those required by ISO—this is why we went to Whistler, to validate it on the terrain.