DESIGN, DEVELOPMENT AND MANUFACTURING IN BARCELONA

Yes, made in Barcelona. And when we say made, we mean it.

We don't produce in another country and then assemble it here and say it's made here.

We don't import parts manufactured abroad to paint them and label them "Made in Spain," as most companies in the sector do.

We truly manufacture, layer by layer, transforming raw materials into products, because only in this way can we control every step of the process and guarantee that each piece is a true work of art.

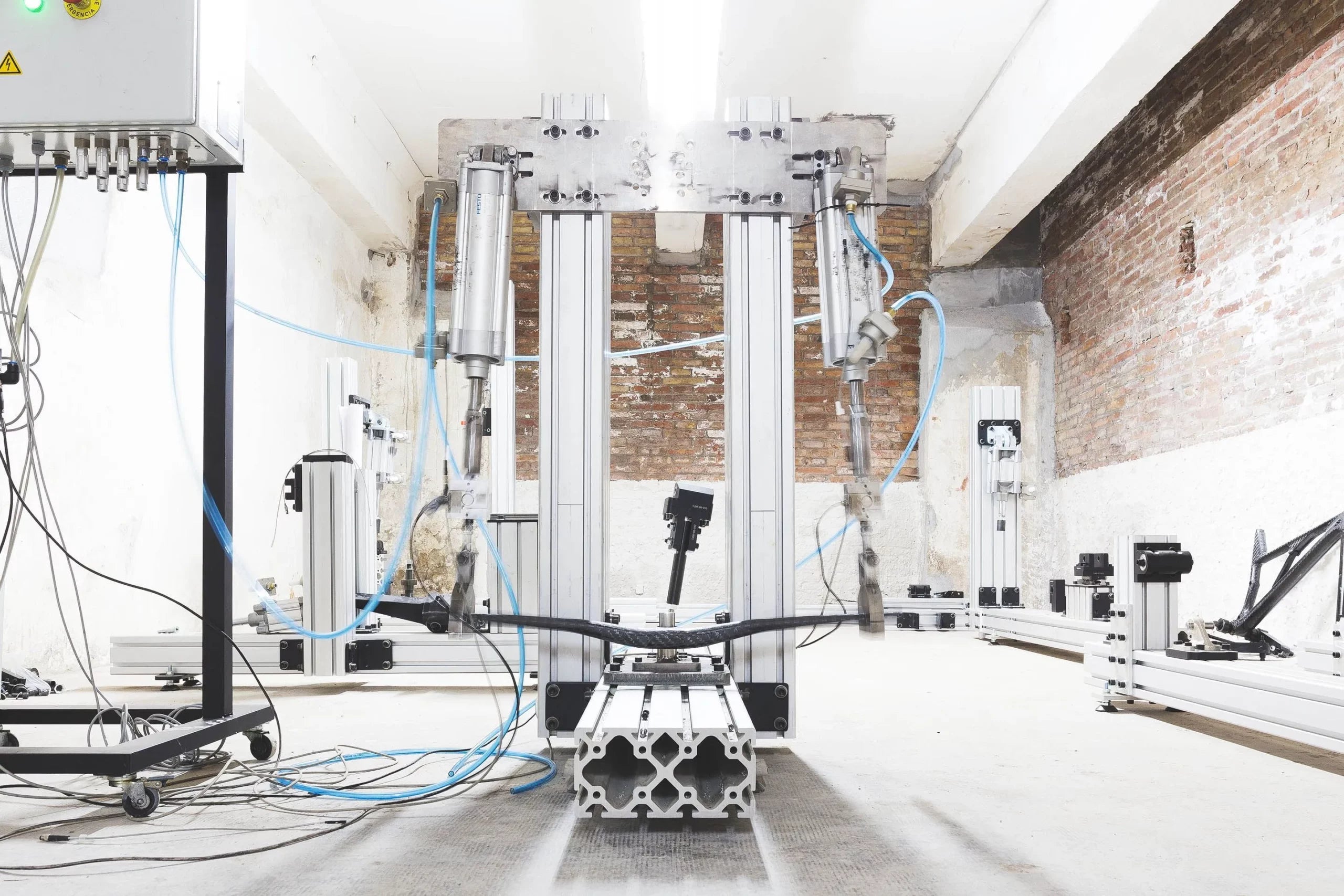

Producing in our own workshop allows us to constantly innovate and develop exclusive technologies and processes that we apply only to our products and that no one else does, without having to adapt to the manufacturing process and materials of a supplier who uses the same materials for all the brands they manufacture for.

That's why our products are unique and unlike anything you've seen before.

That's why Gemini isn't just a pretty logo or a flashy color. We don't offer the lightest components because we simply decided to remove material. Behind every component are many hours of engineering and development, calculating and optimizing each piece, manufacturing with the utmost care and under the highest quality standards. That's why our components are unlike anything you've seen before.